Rice is grown in fertile lands of Sindh and Punjab province of Pakistan where BFI has numerous rice farms, here the rice is grown with extra care by the specialized farmers. These farms are spread in acres and contains de-husking and parboiled units which confirms to international standards.

AGRICULTURAL LAND

We use contractual farming in different regions of Pakistan which is also used for RND purpose to cultivate the authentic Basmati rice. This adds an edge to our firm and gives us a high share in our country.

HUSKING UNIT

The area of location is stretched at approximately 3,00,000 square feet. The factory holds the capacity of producing 750 metric tons. Having husking units is the key to controlling quality by procuring high specification paddy directly from farms which is later processed in our factories

STEAMING & PARBOILED UNITS

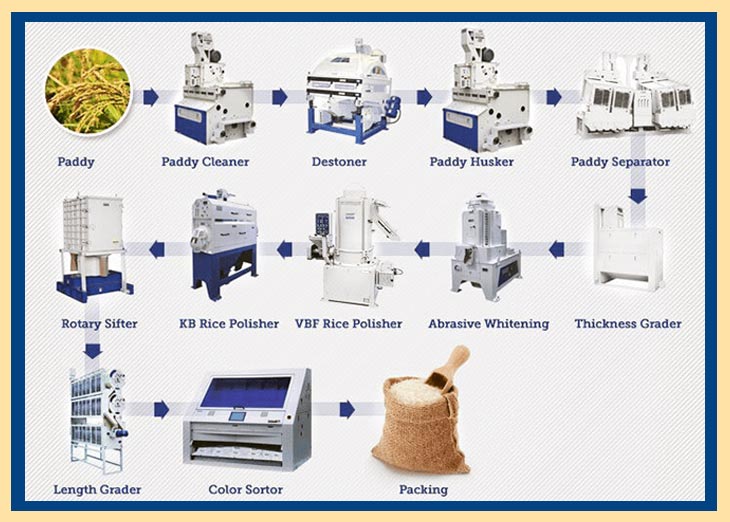

We have fully automatic rice mill plants and modern mill line which includes husking, steaming and parboiling units. We use treated water for our quality assurance in the manufacturing process. These units produce 250 metric tons of paddy rice per day that compliance with the international quality standards.

REPROCESSING UNIT

A sole being has a reprocessing unit in an industrial area situated approximately on 1,00,000 square feet with the production capacity of 250 metric tons of finished rice per day. The factory has the capacity to store 5000 metric tons finished product under strict quality check.

Apart from this we own another mega reprocessing unit at HUB RIVER ROAD, TALUKA KEAMARI, KARACHI. on a stretch of about 3,00,000 square feet. This is the largest operational port of Pakistan where our unit produces 1000 metric tons finished rice per day and thus the storing capacity is even larger, around 25000 metric tons. This fully mechanized hi-tech plant process excellent quality rice and enables us to deliver timely.